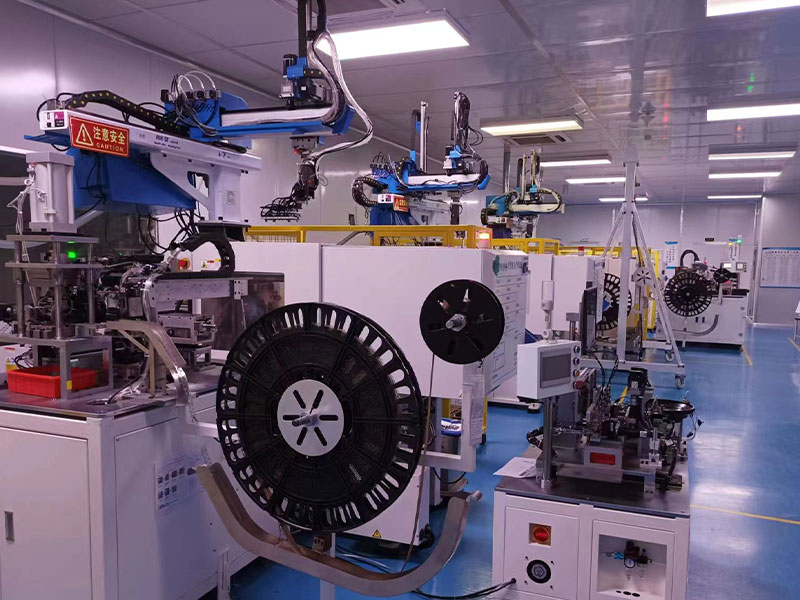

The company has advanced auxiliary equipment and is equipped with more than 30 four axis and six axis robots for molding. All molding production is automated.

The company's molding production and feeding operations are fully automated, which not only improves the quality of products but also reduces the labor intensity of workers.

The company has complete automation equipment and a total of more than 30 automatic turntable machines, which are at the forefront of technology in the East China region.

There are multiple complete production lines and more than 130 skilled professional operators, which can meet the product quality requirements of domestic frontline communication, automotive and other companies.

There are over 40 imported and domestically produced molding machines, producing various products such as 3C products, automotive parts, electronic products, connectors, etc., with an annual output of 3 billion PCS

Two slow wire cutting machines for industrial production in western Japan

6 Sadik discharge motors and 2 Corius CNC processing equipment can process about 10 sets of molds per month